How to Make Chocolate Bars?

Chocolate bar is a common casual snack, which is sold in supermarkets, stores and small shops. It not only has a delicate and sweet taste, but also has a rich aroma, which is deeply loved by consumers. Especially for those who love sweets, chocolate bars are a very good choice, which can meet the needs of most people.

So, do you know how the chocolate bar is made and what is its processing technology? With the advancement of science and technology and the improvement of people's consumption level, higher requirements are put forward on food, and the process of producing chocolate bars has also been greatly improved. The Chocolate Bar Machine is a newly launched chocolate bar machine specially used for making chocolate bars. device of.

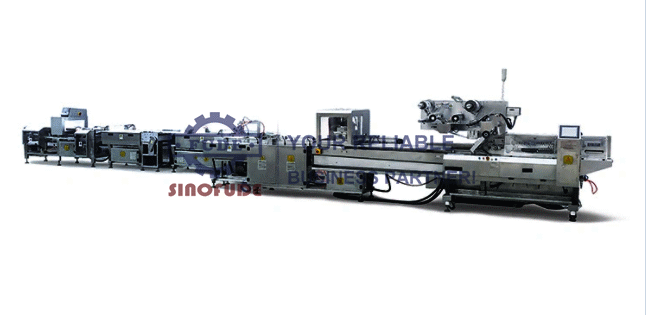

The chocolate bar production line is based on the advanced technology at home and abroad, and is carefully designed and manufactured by a professional R&D team. It shows excellent performance in making chocolate bars. Its appearance and quality are very good. Compared with the process of making chocolate bars, it has more prominent advantages, and its main features are as follows:

Features of Chocolate Bar Making Machine:

1. The structure of the whole machine is very reasonable, the control is simple, and the stability is high.

2. Double frequency conversion control, stable operation, convenient maintenance and trouble-free.

3. Superb smart touch screen and separate digital display temperature control system, simple parameter setting, easy to change product size.

4. The man-machine interface can quickly and clearly access all necessary areas and functions, such as product size changes, multi-zone temperature control, error indicators and troubleshooting procedures.

5. The whole machine is a mechatronics equipment, with very precise positioning, close matching of molds in the forming part, good forming effect, fine processing process, and beautiful finished products.

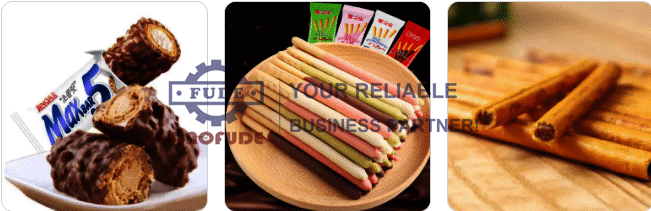

The chocolate bar production line can produce various chocolates such as single flavor, two flavor, three flavor, paste center filling, nut center filling, etc. according to the different configurations of the machine. The production of chocolate bars can basically be divided into six steps: raw material mixing, fine grinding, refining, temperature adjustment, and molding. The process is as follows:

1. Mixing of raw materials: mix sugar, milk powder, cocoa butter, cocoa mass and other auxiliary materials evenly.

2. Fine grinding: This process refers to grinding the uniformly mixed raw materials. This step can be divided into coarse grinding and fine grinding according to the size of the raw and auxiliary material particles.

3. Refining: The main purpose is to remove the volatile acid, moisture, and odor of the slurry, and at the same time produce a burnt odor, highlighting the flavor of chocolate. To

4. Temperature adjustment: The purpose of this step is to crystallize the cocoa butter in the slurry to form stable crystals, which are expressed with a black luster, and at the same time extend the shelf life of the food.

5. Pouring mold molding: Pouring mold molding is to pour liquid chocolate into a quantitative model tray to form a dense texture state, produce obvious volume shrinkage, and finally form various and colorful beautiful chocolate products.

Chocolate Bar Machine is an upgraded new type of equipment. By changing molds or certain raw materials, it can also produce a variety of bar biscuits. Such as date bars, energy bars, fruit bars, protein bars, vegetarian bars, cereal bars, oatmeal bars, Nutrition bars, snack bars, etc., have the characteristics of one machine with multiple functions, which are very suitable for processing various snack foods.

The above is about how to make chocolate bars. Nowadays, the process of making chocolate bars is more and more advanced. The chocolate bar making machine can produce various types of food to meet the different needs of consumers. At the same time, it is constantly improving. Among them, I believe that the future development will be bright.

Telephone :+86-13917870833

Telephone :+86-13917870833 WhatsApp :8613917870833

WhatsApp :8613917870833 Email :info@sinofude.com

Email :info@sinofude.com