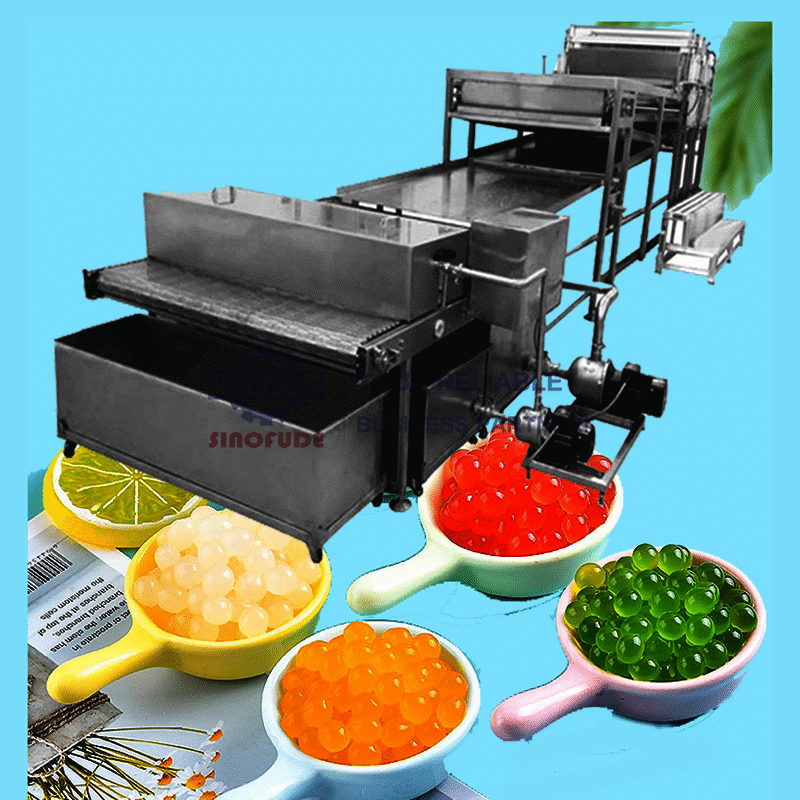

What are the Advantages of Popping Boba Making Machine?

In recent years, with the improvement of the public economy level, there are also higher requirements for food, and more pursuit of diversification of types. popping bobas is a very popular and unique food, and it will burst in the mouth with the slightest bite. , So you can taste the delicious juice liquid, the taste is very unique.

We are a well-known popping boba manufacturer in the industry. The popping bobas we produce have very high sales in the market. In order to further improve our production technology level, we have purchased and used the Popping Boba Machine after some inspections. , This equipment has outstanding performance and superior quality, which brings great vitality to our workshop.

What are the advantages of the popping boba making machine?

1. The degree of automation is high, the production efficiency is very high, and it can provide manufacturers with greater output in the same time.

2. The whole machine adopts food-grade components, and the accessories adopt internationally renowned brand components, which are reliable in quality and can be used for a long time.

3. With continuous work and material recycling design, it can effectively avoid waste.

4. Using the PLC control system and the touch screen operation mode, the operation is very simple, and the production can be carried out without technical talents.

5. It can be adjusted according to production needs, and can produce different sizes of blasting beads, which is very flexible in use.

The popping boba making machine has obvious advantages, and its performance can be put into practice in actual production, and it can be used very well. The bursting bead making machine is composed of a titration system, a forming system, a filtration system, a cleaning and curing system, a filling and sealing system, a sterilization system, and a PLC central control system. It can automatically complete the juice blending, titration, forming, filtering, cleaning, Filling and sealing and sterilization and other production processes, which is a technological level that cannot be achieved by traditional equipment.

What is the difference between popping bobas production machine and traditional equipment?

1. popping bobas production machine with fully automated production method, production efficiency is very high, and no human intervention, ordinary workers can easily operate, only need to set the program in advance to carry out automated production, higher than the traditional equipment production efficiency.

2. The use of popping boba production machine produced by the popping bobas of higher quality, more round and transparent, brilliant, and traditional equipment produced by the popping bobas to do a comparison, you can clearly see the gap between the high quality of popping bobas in the market sales to be higher.

3. Production costs are closely related to the development of manufacturers, popping bobas production machine using energy-saving design and material recovery design, the operation of the process of lower energy consumption, but also does not cause waste of raw materials, can further help manufacturers to reduce production costs and gain greater market competitiveness.

After using Popping Boba Machine for a period of time, we obviously feel its advantages, whether in terms of production efficiency or production quality and production costs, have been greatly improved, completely abandoned the shortcomings of traditional equipment, so that our production process level has been very much improved.

Now we have become a very friendly relationship with the manufacturer, the manufacturer's service is very perfect. Not only can provide us with cost-effective equipment, but also to provide us with quality formulas, the subsequent use of all the problems encountered. The manufacturer will provide a perfect solution, so that our use is very secure.

With the help of the popping boba manufacturing machine, we effectively improve the quality of production, further expand the market and enhance brand awareness. We very much approve of the equipment, but also hope that the manufacturer can develop more equipment with superior performance. So that we can contribute to the development of the food industry!

Telephone :+86-13917870833

Telephone :+86-13917870833 WhatsApp :8613917870833

WhatsApp :8613917870833 Email :info@sinofude.com

Email :info@sinofude.com