What is a Confectionery Machine?

The candy production line is an assembly line for the production of candies. It is an advanced continuous equipment for the production of different sizes of candies. It is also an ideal equipment for producing high-quality products, saving manpower and occupying space. The machine adopts continuous casting automatic demoulding, fan forced cooling and other devices. Integrated automatic pouring machine.

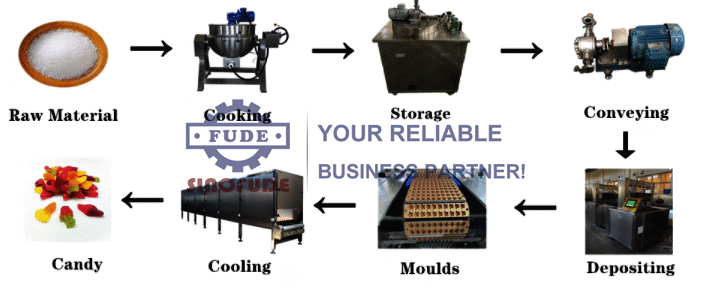

The production line is composed of jacketed dissolving pot, gear pump, storage filter, storage tank, discharge pump, color and fragrance mixer, color and fragrance mixer, pouring device, cooling channel, electric control cabinet, etc. The whole process is fully automatic. Including mold heating, pouring, template vibration, cooling, demoulding and conveying.

Confectionery Machine adopts advanced technology and reasonable design. It is an automatic assembly line integrating electricity, light, gas and machine. It solves the problems of small production scale, short shelf life, and complicated operation. It has high automation, simple operation and long product shelf life. The characteristics of this product are favored by Chinese food manufacturers.

Features of candy machine:

1. It can automatically mix flavors, pigments, and acid in an accurate quantity ratio, and the operation is very simple.

2. The high degree of automation ensures efficient production, saves time and labor, and achieves the goal of reducing costs.

3. The PLC, touch screen, and servo drive systems all adopt imported brands, with more reliable and stable performance and long service life.

4. The machine has simple and compact structure, menu-type operation interface, convenient operation and maintenance, high efficiency, low noise and stable performance.

5. The amount of placement can be easily changed through the setting data on the touch screen. More accurate deposition and continuous production minimize product waste.

Main production process:

Dissolving of raw materials → transportation → storage → ingredients → preheating → micro-film cooking → discharging → flavoring and coloring → putting rod → pouring → cooling → demoulding → conveying → packaging → finished product

1. Ingredients: The first step in the production of candies is to make ingredients. The main ingredients and auxiliary materials must be balanced and matched, so as to ensure the quality and taste of the final product.

2. Boiled sugar: The purpose of boiled sugar is to re-evaporate and remove part of the water in the solution, so that the final candy can reach a high concentration and retain low residual moisture.

3. Forming: boil the massecuite to the specified concentration, then cool it appropriately, then add the appropriate amount of coloring and seasoning, mix well, and then it can be formed.

4. Packaging: After the candy is formed, in order to extend its shelf life, packaging is very necessary. Packaging is an indispensable means of protection for candy. The role of packaging is to prevent or delay quality changes.

The candy production line is automatically completed from dissolution, cooking, color and flavor mixing, deposition, cooling to final candy packaging. This candy making equipment can make soft candies, hard candies, flat lollipops and spherical lollipops. It can be replaced by molds. Candies of different shapes are made with reasonable design of the whole line, compact structure, simple operation and high production efficiency.

The candy production line has shown very superior performance in all aspects. Not only does it have good quality and long service life, the candy produced is also very high-quality, in line with food safety and sanitation standards, and it can produce different types of candy to meet the needs of consumers. Different needs save time and labor costs in the production process, and bring considerable benefits to the candy processing factory.

The above is the relevant introduction to Confectionery Machine, mainly talking about the function, characteristics and production process of the production line. I believe everyone has a certain understanding of this, and I hope it will be helpful to you.

Telephone :+86-13917870833

Telephone :+86-13917870833 WhatsApp :8613917870833

WhatsApp :8613917870833 Email :info@sinofude.com

Email :info@sinofude.com